Helmet Visor Making Service: The Perfect Solution for Your Brand

1. Why An Tran Hard Coating is your premier choise for helmet visor making?

Helmet visors play an essential role in safeguarding riders’ eyes from debris, insects, UV rays, and other hazards encountered during transportation. The manufacturing process of helmet visors demands meticulous attention to detail and adherence to stringent quality standards to guarantee the safety and functionality of these components. Recognizing the complexities involved, many businesses opt for helmet visor outsourcing services to optimize their production processes and gain access to specialized expertise.

An Tran Hardcoating is proud to be a leading provider of helmet visor making services in Vietnam. An Tran Hardcoating boasts extensive experience in the helmet manufacturing industry. With our team of highly skilled technicians, cutting-edge machinery, and professional production processes, we are committed to meeting all customer requirements.

At An Tran Hardcoating, we are committed to providing our customers with a seamless experience. We offer a comprehensive range of services, from initial visor processing to final coating, ensuring that your products meet the highest standards of quality and performance.

At An Tran Hardcoating, we are committed to providing our customers with superior helmet visors that meet the highest standards of quality and performance. An Tran Hardcoating is committed to providing high-quality helmet visors that meet all quality standards.

An Tran Hardcoating offers helmet visor processing services with a wide range of designs. These designs encompass a variety of models, styles, and colors to cater to the diverse needs and preferences of our customers.

An Tran Hardcoating consistently offers customers competitive processing rates that help them save on production costs.

2. Helmet visor making process

2.1. Material Preparation

Polycarbonate (PC) Resin: Polycarbonate (PC) is the most common type of plastic used for manufacturing helmet visors. PC resin is highly durable, transparent, impact-resistant, and offers excellent UV protection.

Molds: Helmet visor molds are typically made from steel and designed to the exact shape of the desired visor.

Additives: Various additives can be incorporated into PC resin to enhance its properties, such as improving ductility, scratch resistance, or anti-fogging capabilities.

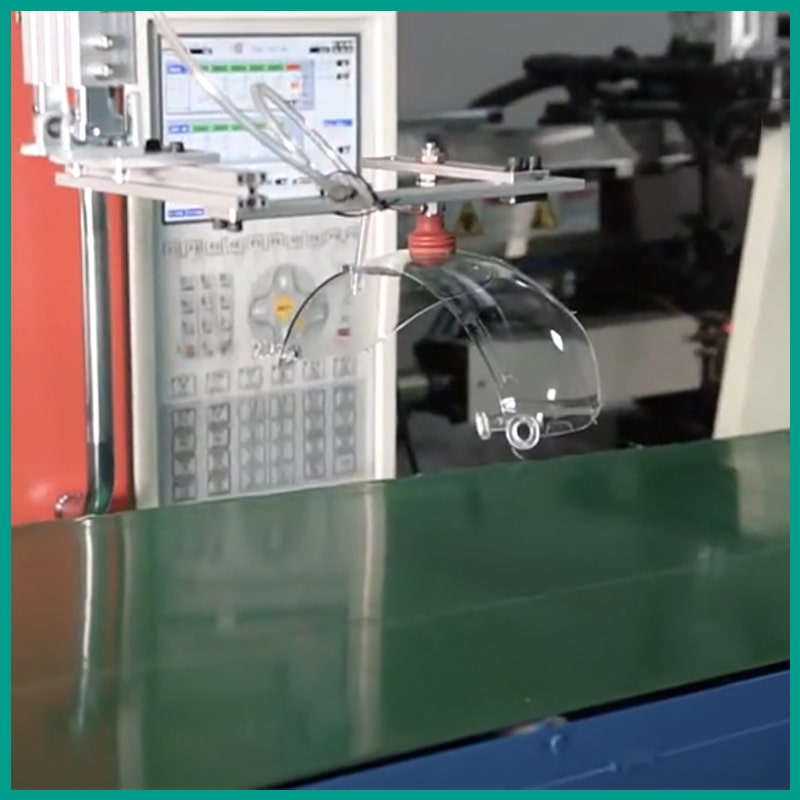

2.2. Plastic Injection and Cooling

Molten Plastic Injection: Molten PC resin is injected into the mold under high pressure, forcing it to conform to the desired shape of the helmet visor.

Cooling and Solidification: The injected plastic is then cooled to allow it to solidify and harden into the desired shape.

2.3. Trimming and Finishing

Trimming Excess Material: Once the visor has cooled and solidified, it is removed from the mold and excess material is trimmed away.

Surface Finishing: The trimmed visor undergoes surface finishing processes, such as hardening or applying a mirror coating, depending on the specific requirements.

2.4. Quality Inspection

Helmet visors undergo rigorous quality assurance (QA) testing to ensure they meet the highest safety and performance standards. These tests are crucial for guaranteeing the protection and durability of the visors, ensuring the safety of helmet wearers such as: durability testing, impact resistance testing, UV protection testing, scratch resistance testing,…

3. Contact us

Contact An Tran Hard Coating for a free consultation and quotation:

Email: ads.athardcoating@gmail.com

Mobile/Zalo: 0906 735 520

Hotline: 1900 9232